8 Notorious Shed Problems and How I’ve Solved Them

By Paul Johnston

By Paul Johnston

1. Ugly Appearance.

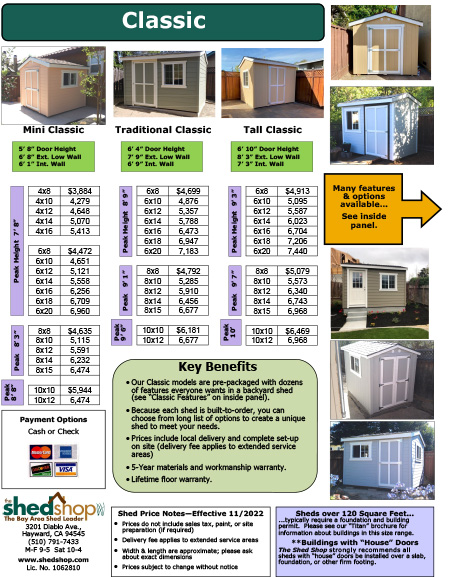

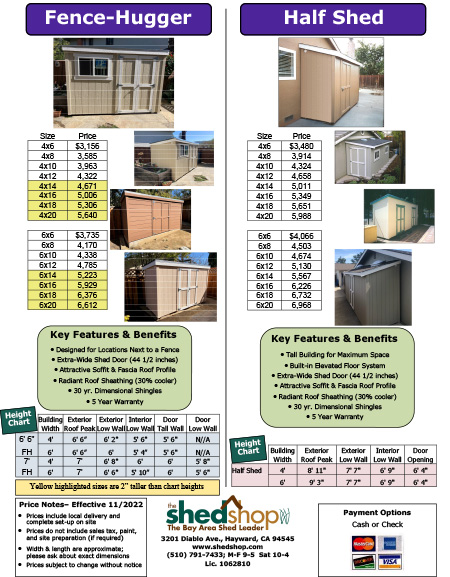

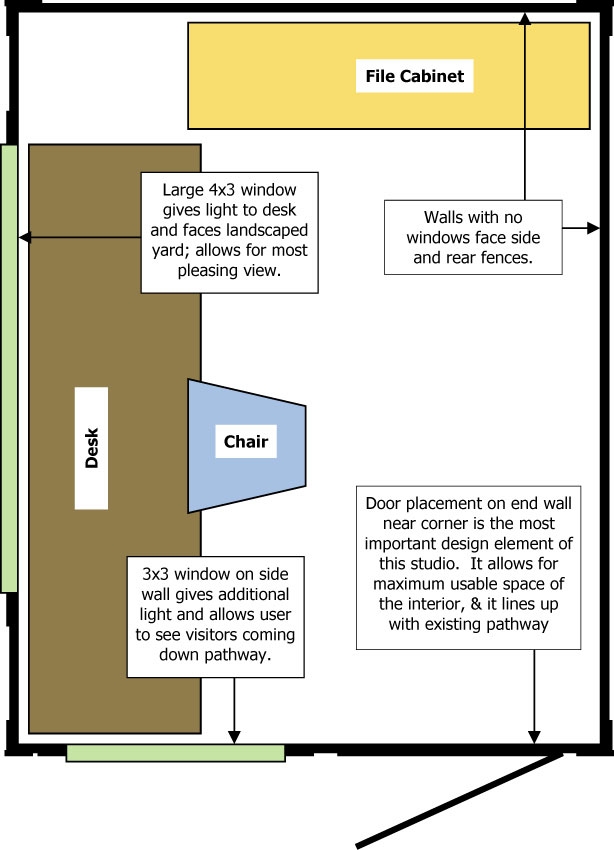

Are you proud of your home’s appearance? Is your yard nicely landscaped? Maybe you have put off buying a shed because sheds have a notorious reputation for being ugly. We believe an attractive shed begins with all-wood shed construction…. but that’s just the beginning. Residential siding and roofing, choice trim, gabled soffit & facia roof profile, strategically placed doors & windows, balanced roof pitch and shed height, and optional house type doors all contribute to our shed’s attractive appearance.

2. Premature Floor Rotting.

We’ve solved this shed construction problem by including a four component floor system… cement blocks, treated runners, floor joists, and exterior grade 3/4″ flooring. The blocks and treated runners elevate the floor allowing airflow under the floor so it stays dry. To insure the shed stays elevated, we offer a re‐shimming service for a nominal fee as long as you own your shed…. ask for details.

3. Moisture Condensation and/or Leaks.

This notorious shed problem is common in metal sheds. We eliminate condensation by building our sheds out of wood only, which has good insulating characteristics. Leaks on our sheds are discouraged by at least nine specific items including… self‐sealing shingles, galvanized drip edge, “Synfelt” roof underlayment, all trim is caulked, positive roof overhang, self‐flashed roof vents, out‐swing shed doors, etc.

4. Inability to Have a Shed Customized to Your Needs.

Most sheds come configured only one way, with very few sizes to choose from. But The Shed Shop builds each shed individually for each customer based on their needs and preferences. There are physical limitations, and we do not offer unlimited customizing, but you can choose between several styles and almost 30 sizes. Choices include door and window placement, and there are many optional upgrades to choose from. Not sure what to order?… We’ll take you through a thorough shed consultation process to help with these decisions.

5. City Ordinance Problems.

Watch out for a shed company that tells you not to worry about permits or codes. As the property owner, you are responsible for local “zoning” or “planning” codes that may apply to your property. Although local shed codes are not always enforced, we recommend you make every effort to be in compliance. To help in this area, we keep a file of local city and county ordinances in the areas we serve. We will help you understand these codes and help you design your shed so it meets them. You may not need one, but if your shed requires a “building” permit, we offer permit procurement services that will give your shed project the best chance of getting approved.

6. Door Problems.

Since it is the only moving part, it makes sense that sheds can have door problems. Our problem free door is the result of years of practice and know-how. Our door is braced, trimmed, glued, caulked, screwed, nailed, and hinged with heavy duty “T” hinges. You would need a heavy duty pry bar and reciprocating saw to take our door apart.

7. Flimsy Construction.

Most sheds are developed with low cost in mind. This approach usually leads to poor construction. A Shed Shop building is constructed in a manner similar to house construction. No bracing component is left out that should be there including floor joists, double top plates, ridge beams, double corner studs, and extra braced door & window headers. Our shed walls are so sturdy, they can comfortably support shelving from top to bottom.

8. Lack of a Trained Shed Assembler.

Who is going to build your shed? You may have a friend or relative who can do it, but when? And you still must purchase all the materials at retail price. Every shed we sell includes installation by our own trained employees; we do not use sub-contractors as is the practice of some shed companies. Listen to one satisfied customer’s comments….

“We wanted to write to let you know how happy we are with our new shed, and what a good job Aaron and Nick did in building it. They were prompt, personable, astonishingly efficient and meticulous, happy to answer questions, and did a good job of cleaning up. We are AMAZED that they could build such a sturdy and attractive shed so quickly. We also appreciate the well thought out design that makes that possible! It’s immediately apparent that it’s a quality building, even if it is only a shed.”

– Jack & Gail in Richmond.

“Radiata Pine” 3/4 inch Plywood Floor

“Radiata Pine” 3/4 inch Plywood Floor Louisana Pacific “SmartSide” Siding

Louisana Pacific “SmartSide” Siding Radiant Barrier Roof Sheathing

Radiant Barrier Roof Sheathing Wood waste is recycled

Wood waste is recycled Low-E Glass Double-Pane Jeld-Wen Windows

Low-E Glass Double-Pane Jeld-Wen Windows

By Paul Johnston

By Paul Johnston